Asphalt Mixing Plant supporting equipment

Brand: BituRock

Product origin: WUXI, JIANGSU,CHINA

Delivery time: 30-40 DAYS

Supply capacity: 5 SETS PER MONTH

Asphalt mixing plants require a variety of supporting equipment to ensure that the production process runs smoothly and efficiently. In this article, we will explore the different types of supporting equipment used in asphalt mixing plants.

1. Cold feed systems: Cold feed systems are responsible for supplying the aggregates needed for the production of asphalt concrete. The system is equipped with sensors that ensure accurate measurement of the aggregates and efficient handling of aggregates.

2. Drying system: The drying system is responsible for removing moisture from the aggregates before they are mixed with the binder and filler materials to produce asphalt concrete. The system is equipped with a drum dryer that is heated by a burner.

3. Dust collection system: The dust collection system is responsible for collecting and disposing of any dust generated during the production process. The system ensures environmental friendliness, worker safety, equipment protection, increased efficiency, and compliance with regulations.

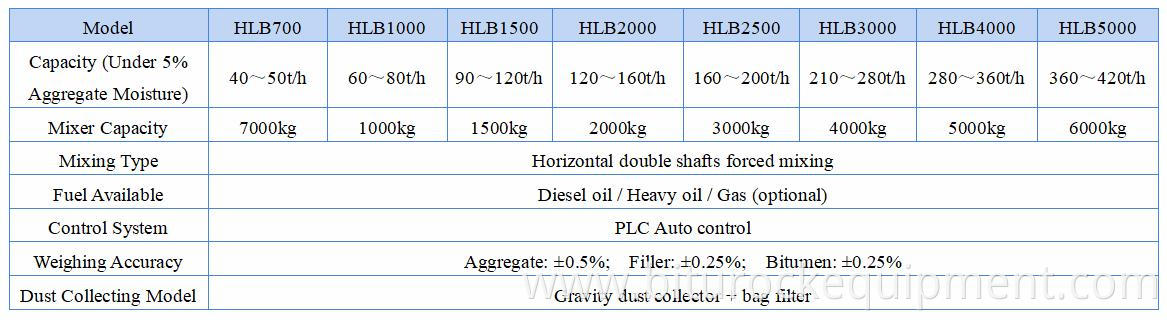

4. Mixing tower: The mixing tower is responsible for mixing the aggregates, binder, and filler materials to produce asphalt concrete. The tower is equipped with sensors that monitor the temperature, pressure, and other parameters to ensure accurate mixing of materials.

5. Control system: The control system is responsible for ensuring that the production process is efficient, accurate, and consistent. The system is equipped with sensors that monitor the temperature, pressure, and other parameters to ensure that the asphalt concrete is produced to the desired quality.

6. Paving equipment: Paving equipment is responsible for laying down the asphalt concrete on the road surface. The equipment is equipped with sensors that monitor the temperature and thickness of the asphalt concrete being laid down, ensuring that it is placed correctly and consistently.

In conclusion, asphalt mixing plants require a variety of supporting equipment to ensure that the production process runs smoothly and efficiently. Cold feed systems, drying systems, dust collection systems, mixing towers, control systems, and paving equipment are all essential components of asphalt mixing plants. These supporting equipment components ensure accurate measurement of aggregates, efficient handling of aggregates, removal of moisture from the aggregates, collection and disposal of dust, accurate mixing of materials, efficient production process, and consistent quality of asphalt concrete.